- This topic is empty.

-

AuthorPosts

-

2025-10-28 at 9:19 am #86808

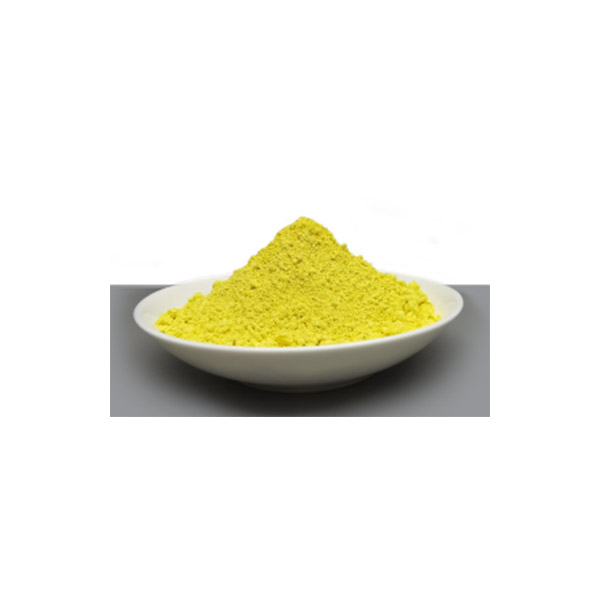

Nickel titanium yellow pigment, a versatile and intriguing colorant, has captured the attention of artists, industrial manufacturers, and scientists alike due to its distinctive properties and wide-ranging applications. This pigment, derived from a unique alloy of nickel and titanium, offers a vibrant yellow hue that is both durable and adaptable. The use of D-Ray Nickel Titanium Yellow Pigment not only enhances the aesthetics of the product, but also ensures color consistency and long-term stability, meeting the market's growing demand for high-quality, high-performance pigments. Its unique metallic composition also gives this pigment a subtle metallic luster, making it equally popular in artistic creations and high-end design projects.

Unique Characteristics

Chemical Composition and Stability

Nickel titanium yellow pigment is composed of a nickel-titanium alloy, known scientifically as NiTi or Nitinol. This alloy is renowned for its shape-memory effect and superelasticity, but it also exhibits exceptional chemical stability when used as a pigment. Resistant to oxidation and corrosion, nickel titanium yellow maintains its vibrant color and integrity even under harsh conditions, making it ideal for outdoor applications and high-temperature environments.

Color Properties

The yellow hue of nickel titanium yellow pigment is a result of its specific alloy composition and crystal structure. This pigment offers a pure, bright yellow that is highly saturated and consistent across different batches. Its color is also lightfast, meaning it resists fading over time when exposed to sunlight, making it a preferred choice for long-lasting color applications.

Environmental Impact

In terms of environmental sustainability, nickel titanium yellow pigment presents a mixed picture. While the alloy's durability and longevity reduce the need for frequent replacement, the mining and refining of nickel and titanium can have significant environmental impacts. However, ongoing research into more eco-friendly production methods and recycling processes holds promise for a more sustainable future for this pigment.

Applications in Art and Design

Paints and Coatings

Nickel titanium yellow pigment's resistance to fading and chemical degradation makes it an excellent choice for paints and coatings used in exterior applications such as building facades, automotive finishes, and marine coatings. Its vibrant color adds a touch of brightness and visual appeal to these surfaces, enhancing their overall aesthetic quality.

Plastics and Polymers

In the plastics and polymers industry, nickel titanium yellow pigment is used to colorize a variety of materials, including thermoplastics, elastomers, and composites. Its durability ensures that the color remains consistent throughout the manufacturing process and in the final product, even when subjected to molding, extrusion, or other forming techniques.

Ceramics and Glass

Due to its high temperature stability, nickel titanium yellow pigment is also suitable for use in ceramic glazes and glass manufacturing. It adds a striking yellow hue to ceramic tiles, pottery, and glassware, enhancing their decorative value and making them more appealing to consumers.

Industrial Applications

Aerospace and Aviation

In the aerospace and aviation industries, nickel titanium yellow pigment is valued for its ability to withstand extreme temperatures and maintain color integrity. It is often used in coatings for aircraft engines, exterior surfaces, and other components that are exposed to high heat during operation.

Electronics and Semiconductors

Nickel titanium yellow pigment's chemical stability and resistance to electrical discharge make it a suitable choice for use in electronic components and semiconductor packaging. It can be incorporated into coatings and encapsulants to provide color and protection without compromising the performance of electronic devices.

Medical Devices

The shape-memory and superelastic properties of nickel titanium alloys are well-known in the medical device industry. While nickel titanium yellow pigment itself is not used directly in medical implants or devices due to its opacity, it does find application in coloring surgical instruments, medical packaging, and other ancillary products.

Future Prospects and Research Directions

Sustainable Production

As environmental concerns continue to rise, research into more sustainable production methods for nickel titanium yellow pigment is crucial. This includes exploring alternative raw materials, improving recycling processes, and reducing energy consumption during manufacturing.

Enhanced Properties

Efforts are also underway to develop nickel titanium yellow pigments with enhanced properties, such as improved lightfastness, increased chemical resistance, and better dispersion in various media. These advancements will further broaden the pigment's application potential and enhance its performance in existing markets.

New Applications

With its unique combination of durability, color consistency, and adaptability, nickel titanium yellow pigment holds promise for new applications in emerging fields such as renewable energy, advanced materials, and biotechnology. Researchers are continuously exploring ways to leverage the pigment's properties to create innovative solutions for these and other industries.

Conclusion

Nickel titanium yellow pigment stands out as a versatile and high-performance colorant with a wide range of applications across multiple industries. Its unique chemical composition, vibrant color properties, and resistance to environmental degradation make it an ideal choice for art, design, and industrial use. As research continues to advance, the future of D-Ray nickel titanium yellow pigment looks bright, with new applications and enhanced properties on the horizon.

https://www.draycolor.com/exploring-the-unique-characteristics-and-applications.html

http://www.draycolor.com

Zhejiang D-Ray Technology Co., Ltd -

AuthorPosts

- You must be logged in to reply to this topic.