- This topic is empty.

-

AuthorPosts

-

2025-09-23 at 4:14 pm #86658

Printed Circuit Boards (PCBs) form the backbone of modern electronics, acting as platforms for mounting and connecting electronic components. Their importance becomes even more pronounced in healthcare, where precision, reliability, and safety are paramount. Medical PCBs power devices ranging from diagnostic equipment to life-support machines, ensuring accuracy and durability under stringent conditions.

Shenzhen Zinpon Electronics Co., Ltd., a professional PCB and PCB assembly manufacturer, plays an essential role in this ecosystem. With expertise in developing boards tailored to the medical industry, the company provides solutions that combine high-quality materials, advanced manufacturing processes, and rigorous testing. By integrating engineering excellence with industry-specific requirements, Zinpon Electronics helps clients achieve efficiency and reliability in critical applications.

This article explores the wide scope of industrial solutions with medical PCBs, tracing the journey from manufacturing to real-world applications.

Understanding the Role of Medical PCBs

Medical PCBs are specialized boards designed to support medical devices that must perform with extreme accuracy and reliability. Unlike conventional electronics, healthcare equipment demands consistent operation in sensitive environments, where even the slightest malfunction can have severe consequences.

The design of medical PCBs requires careful consideration of factors such as signal integrity, thermal management, and biocompatibility. They often incorporate multilayer designs, high-density interconnections, and special coatings to withstand sterilization processes. Shenzhen Zinpon Electronics Co., Ltd. understands these requirements and ensures its boards meet strict industry standards while aligning with the practical needs of healthcare providers and equipment manufacturers.

Manufacturing Excellence in Medical PCB Production

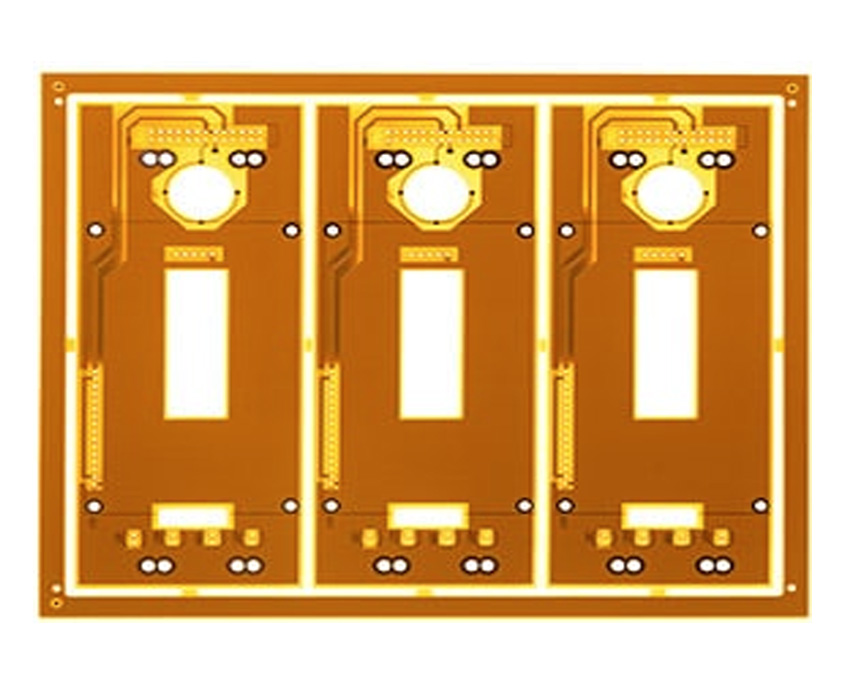

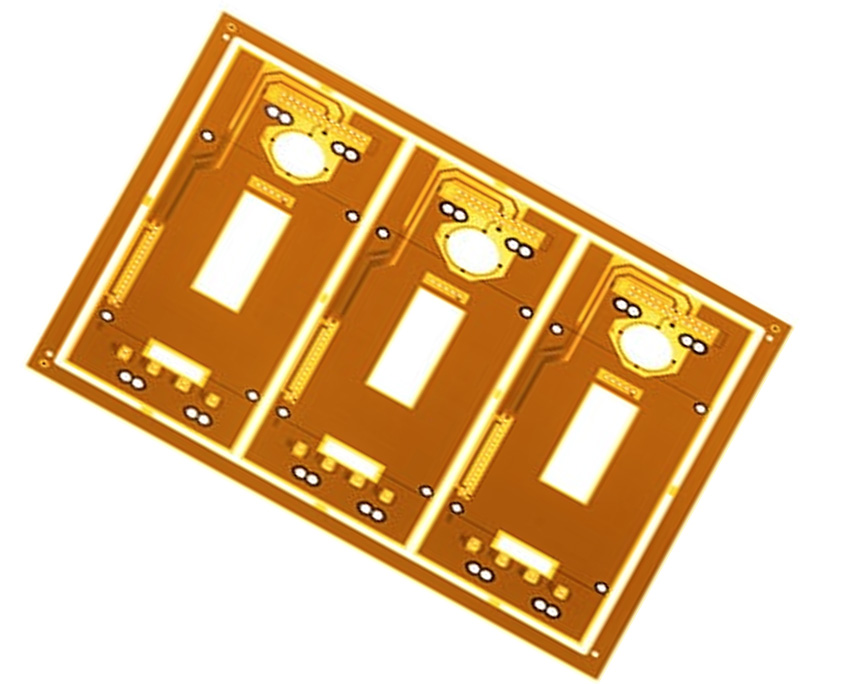

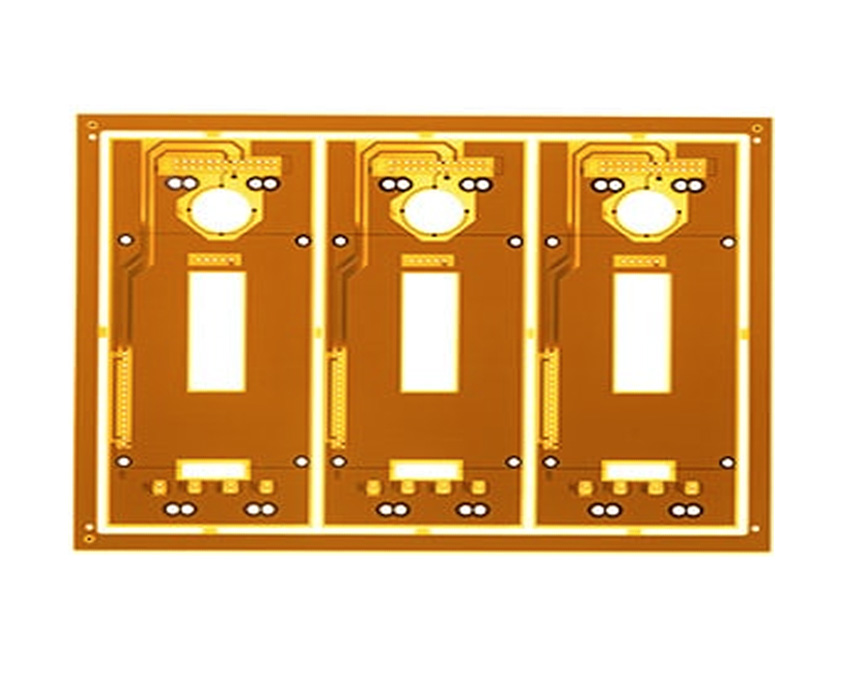

The production of medical PCBs involves sophisticated processes that guarantee precision and quality. From the selection of substrate materials to the application of solder masks, every stage contributes to the reliability of the final product. Materials such as FR-4, ceramics, and polyimide are frequently used, depending on the application and the environmental conditions the device will encounter.

Zinpon Electronics combines advanced machinery with a skilled workforce to manufacture PCBs that meet medical standards. Processes such as photolithography, drilling, plating, and lamination are executed with high precision to ensure fine traces and robust connections. Quality assurance tests are performed throughout the workflow to detect and eliminate defects before boards are delivered to clients.

Importance of PCB Assembly in Medical Devices

While PCB manufacturing lays the foundation, assembly completes the process by integrating components. Medical device assembly requires more than simply placing parts on a board—it involves strict adherence to safety standards and compliance with international regulations. Precision soldering, inspection, and functional testing ensure that each assembled unit performs exactly as designed.

Shenzhen Zinpon Electronics Co., Ltd. offers full assembly services that cover surface-mount technology (SMT), through-hole assembly, and mixed-technology solutions. These services allow medical device manufacturers to benefit from end-to-end solutions, reducing lead times while guaranteeing consistency. By providing both PCB fabrication and assembly, Zinpon ensures clients receive seamless integration between design and production.

Meeting Stringent Quality and Safety Standards

Medical devices are governed by stringent quality and safety regulations, including standards such as ISO 13485 and IPC classifications. Compliance with these standards ensures that devices are safe for patients and effective for healthcare providers.

Zinpon Electronics emphasizes strict quality control at every stage of PCB production. Boards undergo electrical testing, thermal cycling, and functional inspection to verify performance under real-world conditions. Conformal coatings and protective layers are applied where necessary to guard against contamination, moisture, and sterilization procedures. This focus on quality builds trust with clients who rely on Zinpon for critical medical applications.

Integration of Advanced Technologies in Medical PCBs

As medical devices become more sophisticated, the PCBs inside them must support advanced features. High-frequency circuits, miniaturized components, and flexible designs are increasingly common. Flexible PCBs, for example, allow devices to be lightweight and compact while maintaining functionality, making them ideal for portable monitoring systems and wearable medical devices.

Zinpon Electronics invests in the capability to produce multilayer, high-density, and flexible PCBs that meet these evolving demands. By integrating advanced design and fabrication techniques, the company ensures its boards are suitable for next-generation medical equipment.

Applications of Medical PCBs in Healthcare

Medical PCBs are used in a wide variety of healthcare devices, each requiring unique design and performance characteristics. Diagnostic imaging systems, such as X-rays, MRIs, and CT scanners, rely on PCBs to process high-speed data accurately. Patient monitoring systems use compact and reliable boards to track vital signs continuously. Life-support machines, infusion pumps, and defibrillators all depend on PCBs to deliver safe and stable performance.

Shenzhen Zinpon Electronics Co., Ltd. provides solutions tailored to these diverse applications. Its boards are engineered to withstand demanding operating environments, ensuring that healthcare professionals can depend on their equipment in critical situations.

Role of PCBs in Portable and Wearable Devices

The healthcare industry has seen a significant rise in portable and wearable medical devices. These products, which include glucose monitors, portable ECG machines, and smart wearable health trackers, require compact yet powerful PCBs. Flexible and rigid-flex designs are particularly important in this segment, as they allow devices to maintain small form factors while accommodating multiple functions.

Zinpon Electronics specializes in delivering flexible PCB solutions that combine lightweight design with mechanical durability. Such capabilities enable manufacturers to develop innovative wearable devices that support continuous patient monitoring outside traditional healthcare settings.

Thermal Management and Reliability in Medical PCBs

Many medical devices operate continuously or under high workloads, making thermal management a key design consideration. Excessive heat can degrade performance, shorten lifespan, or even cause failure. Effective thermal solutions, such as heat sinks, conductive substrates, and thermal vias, are integrated into PCBs to manage heat dissipation.

Zinpon Electronics applies advanced thermal management strategies in its PCB designs, ensuring consistent performance and preventing overheating. This reliability supports healthcare providers in delivering uninterrupted care and accurate results.

Customization and Client Collaboration

Medical devices vary widely, and each requires a unique PCB solution. Customization plays a critical role in aligning PCB design with device requirements. From adjusting board size and layer count to integrating special coatings and testing protocols, customization ensures compatibility with specific medical applications.

Shenzhen Zinpon Electronics Co., Ltd. collaborates closely with clients to deliver customized PCB and assembly services. Through consultation and technical support, the company provides boards that meet both technical specifications and regulatory requirements. This collaborative approach results in solutions that are both practical and dependable.

Sustainability and Environmental Considerations

Sustainability has become a central theme in electronics manufacturing. Medical PCB production must account for environmental regulations, waste reduction, and material safety. Lead-free soldering, recyclable materials, and environmentally friendly coatings are among the measures adopted by leading manufacturers.

Zinpon Electronics integrates sustainable practices into its operations, ensuring compliance with international environmental standards. This commitment not only protects the environment but also aligns with the values of healthcare organizations striving for sustainable practices.

Conclusion

Medical PCBs form the foundation of devices that define modern healthcare. Their precision, durability, and reliability enable diagnostic imaging, patient monitoring, life support, and wearable health solutions. The journey from manufacturing to application requires advanced processes, strict quality controls, and continuous innovation.

Shenzhen Zinpon Electronics Co., Ltd. stands as a professional manufacturer committed to meeting these demands. By providing both PCB fabrication and assembly, the company delivers comprehensive solutions for the healthcare sector. Its dedication to quality, customization, and sustainability ensures that clients receive boards capable of supporting critical medical applications.

Medical PCBs are more than just components; they are essential elements that empower life-saving technology. With manufacturers like Zinpon Electronics leading the way, the healthcare industry can rely on reliable and high-performance PCBs for safe and effective patient care.

Top Features of Medical PCBs and Their Role in Healthcare Devices

http://www.zinponpcb.com

Shenzhen Zinpon Electronics Co, Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.