- This topic is empty.

-

AuthorPosts

-

2025-07-15 at 2:26 pm #86126

As energy storage systems (ESS) evolve to meet the growing demand for renewable energy, electric vehicles, and backup power solutions, the importance of battery safety and monitoring has never been higher. One critical component in ensuring this safety is the Electrolyte Sensor—a small yet powerful device designed to monitor electrolyte presence and prevent dangerous failures.

In this ultimate guide, we’ll explore what electrolyte sensors are, how they work, where they’re used, and why they’re essential in modern energy storage solutions.

1. What Is an Electrolyte Sensor?

An Electrolyte Sensor is a type of battery monitoring component that detects the presence or absence of electrolyte inside energy storage units such as lithium-ion batteries or fuel cells. In simple terms, it helps ensure the electrolyte—an essential chemical for ion movement—hasn’t leaked, evaporated, or degraded.

Unlike traditional sensors that rely on conductivity or temperature, electrolyte sensors focus on real-time electrolyte status monitoring, which is critical for battery safety, performance, and lifespan.

2. Why Are Electrolyte Sensors Important in ESS?

Electrolyte leakage or depletion can lead to:

-

Reduced battery performance

-

Thermal runaway or fire risk

-

Unexpected shutdowns

-

Costly maintenance or replacements

By using electrolyte sensors in energy storage systems, manufacturers and operators can detect issues early, trigger safety shutdowns, and optimize maintenance schedules. This makes them particularly valuable in:

-

EV battery packs

-

Grid-connected energy storage

-

Solar backup systems

-

Data center UPS systems

3. Key Features of a High-Quality Electrolyte Sensor

When choosing an electrolyte sensor, especially for high-stakes applications like battery energy storage systems (BESS), the following features are essential:

-

✅ Zero power consumption during standby

-

✅ Wide operating temperature range

-

✅ Long service life (typically 10+ years)

-

✅ Quick and accurate detection

-

✅ Compact design for space-limited installations

-

✅ Strong corrosion resistance

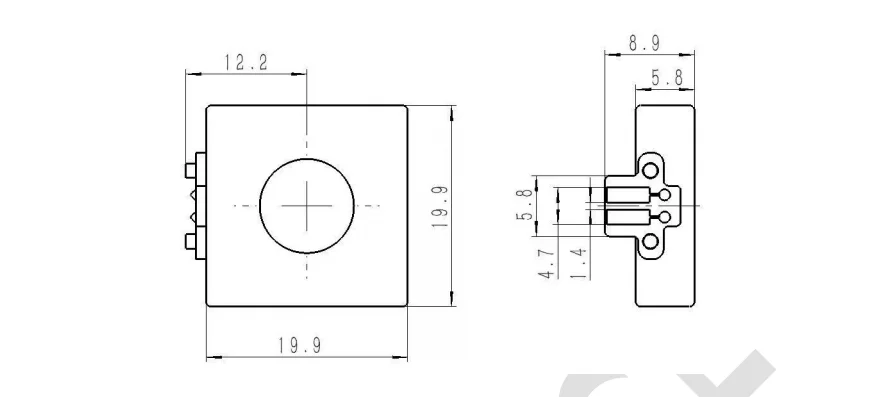

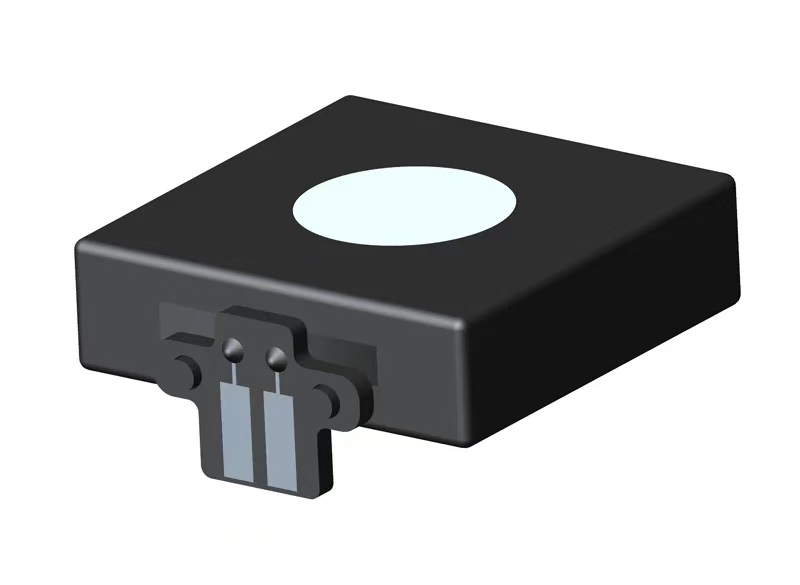

One example is the FC-DJY-100 electrolyte sensor, a compact and reliable model designed specifically for lithium battery packs. It offers excellent chemical resistance and works in low-power environments.

4. Where Are Electrolyte Sensors Commonly Used?

Electrolyte sensors are applied across several sectors, including:

Electrolyte sensors are applied across several sectors, including:

-

Lithium-ion Battery Modules – to prevent damage due to electrolyte leakage

-

Electric Vehicle Battery Compartments – to support safety monitoring systems

-

Battery Cabinets in Data Centers – to avoid system downtime or fire hazards

-

Charging Stations and ESS Cabinets – to comply with industrial safety standards

-

Industrial Fuel Cell Systems – for real-time electrolyte management

As more countries push toward clean energy and EVs, demand for electrolyte sensors in battery safety and diagnostics will continue to rise.

5. Introduction to Prosense: Driving Sensor Innovation

Based in Shenzhen, China, Shenzhen Prosense Technology Co., Ltd. is a high-tech company specializing in the R&D and production of precision gas and electrolyte sensors. With years of experience and a team of skilled engineers, Prosense has become a trusted name in the sensor industry, serving customers across energy, environmental protection, and industrial automation sectors.

Prosense's Electrolyte Sensor series stands out for its:

-

Stable performance

-

Cost-efficiency

-

Easy integration into ESS or EV battery systems

-

Customization for OEM/ODM clients

Their expertise in sensor design ensures safety monitoring is both accurate and maintenance-free, even in harsh environments.

6. How to Select the Right Electrolyte Sensor for Your System

Choosing the right sensor involves balancing your project’s technical requirements and environmental conditions. Here’s a simplified checklist:

Selection Criteria What to Consider Voltage Compatibility Match with your system’s control board Sensitivity Range Depends on the electrolyte type & container Environmental Resistance Humidity, temperature, and corrosion factors Size & Shape Must fit your battery layout Service Life Should match the system’s maintenance cycle For complex or large-scale energy storage deployments, consult a specialized supplier like Prosense for tailored solutions.

7. Future Trends: Smarter Sensors for Safer Energy

As smart energy systems become more common, sensors will play an even bigger role. Upcoming trends include:

-

Integration with IoT platforms for real-time monitoring

-

AI-based fault prediction using electrolyte data

-

More compact, wireless sensor modules

-

Self-calibrating, maintenance-free sensor designs

These innovations will help reduce operational risks and extend the lifespan of high-value battery assets.

Conclusion: Electrolyte Sensors Are Key to Reliable ESS Operation

In today’s energy landscape, safety and efficiency are top priorities. Electrolyte sensors are not just optional components—they are essential for proactive monitoring, risk prevention, and system optimization in energy storage applications.

Whether you're managing a large-scale grid ESS or designing EV battery modules, incorporating a high-quality electrolyte sensor like those from Prosense will add an extra layer of safety and intelligence to your system.

http://www.cnprosense.com

Shenzhen ProSense Technology Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.