- This topic is empty.

-

AuthorPosts

-

2025-10-28 at 2:18 pm #86812

https://www.cable-sf.com/New-Energy-Car-Wiring-Harness.html

Our factory enjoys a distinct edge in customizing high-voltage wiring harnesses for new energy vehicles. Boasting a senior professional team, advanced manufacturing techniques, a rigorous quality control system, and a high-level commitment to environmental protection and safety, we can offer highly individualized solutions to ensure that products not only precisely align with customer demands but also conform to international certification standards. To bring efficient, safe and reliable wiring harness products to customers.

The use of high-quality insulation materials, high temperature resistance, corrosion resistance, to ensure stable operation in extreme environments and pure copper wire is selected to reduce energy loss and improve power transmission efficiency.

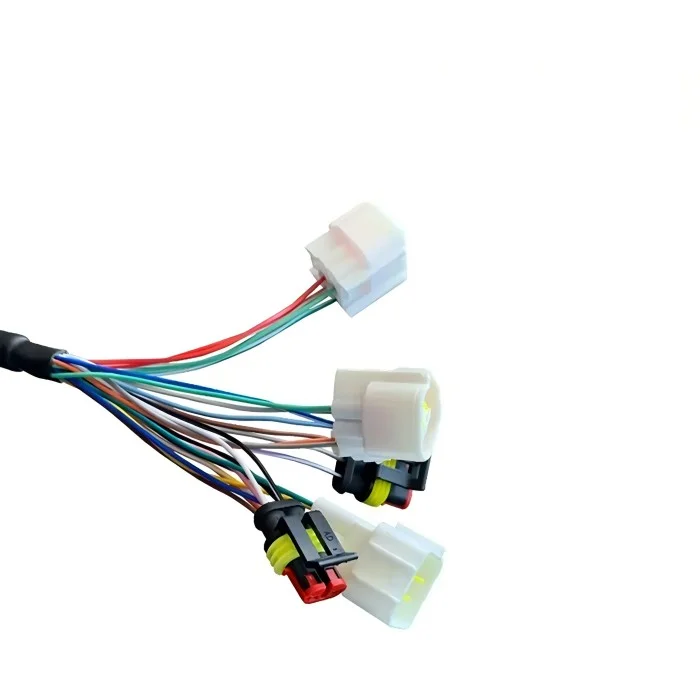

Equipped with various connectors, compatible with a variety of new energy models and According to customer needs, provide one to one customized all kinds of wiring harness products and services.

New Energy Car Wiring Harness

High-Performance Power & Control Harness for Electric Vehicles

We specialize in delivering a new energy car wiring harness solution engineered for modern electric vehicles, hybrid systems, and battery-powered platforms. Our new energy car wiring harness for sale integrates high-voltage power distribution, low-voltage control circuits, sensor and communication lines, all in a robust, reliable package. In particular, our new energy vehicle power battery wiring harness is designed to interconnect battery packs, BMS modules, and vehicle loads with optimal safety and efficiency.

As a manufacturer with strong customization capabilities, we support tailored harness designs to suit your vehicle architecture, battery configurations, and system integration needs.

Key Features & Advantages

1. Optimized for High-Voltage Battery Systems

Insulation materials such as cross-linked polyethylene (XLPE), fluoropolymer, or high-temperature thermoplastics ensure excellent dielectric strength, thermal stability, and resistance to ozone and corona.

Proper creepage and clearance design, shielding or semi-shielding layers, and grounding paths help suppress electromagnetic interference (EMI) and enhance system robustness.

Pure copper or tinned-copper conductors with low resistance reduce energy loss, boosting overall efficiency in the vehicle’s powertrain.

2. Full Customization & Modular Design

We can configure every aspect of the harness: wire gauge, color coding, branch points, connector types, shielding, length tolerances, labeling, and bundling.

Our harnesses are modular and service-friendly (easy disconnection, maintenance, replacement), suited for system upgrades or repair.

Compatibility with standard automotive connector systems ensures integration flexibility.

3. Stringent Testing & Quality Assurance

100% electrical testing on each harness (continuity, insulation resistance, hipot/dielectric test) before delivery.

Optional environmental and reliability tests: thermal cycling, vibration, salt spray, humidity, mechanical fatigue, etc.

Traceability from raw materials (wire batches, insulation batches, connector lots) through production logs, inspections, and final delivery.

4. Material Certifications & Compliance

All materials can meet RoHS, REACH, and applicable automotive industry standards.

5. Durability & Harsh-Environment Performance

Resistant to chemicals, oil, moisture, UV, and mechanical abrasion

Strain reliefs, protective sleeves, grommets, and clamp points are included to protect against bending, vibration, and chafing.

Typical Applications

Main and sub harnesses in electric vehicles

Battery pack-to-vehicle wiring (BMS, HV bus, distribution)

High-voltage harnesses linking battery, inverter, charger, and motor

Control and sensor wiring inside EV / hybrid systems

Internal wiring for charging stations, energy storage systems

Our new energy vehicle power battery wiring harness is especially suited to high-reliability battery systems, providing safe and effective interconnection under demanding automotive conditions.

Why Buy from Us

Specialized expertise in automotive wiring for new energy vehicles

Rich experience in new energy car wiring harness development and integration

High-quality control and traceability through the entire production chain

Flexible customization from small batch prototypes to large-scale production

Commitment to timely delivery, responsive support, and global supply capability

Transparent communication and technical partnership with clients

Packaging & Shipping

Each harness is packaged with protective cushioning, moisture-proof / anti-static bags, and clear labeling

Bundles are secured to prevent damage during transport

Flexible shipping via air freight, sea freight, express courier, or customer-preferred logistics

FAQ

Q1: What information should I provide for a custom order?

A1: Please share your wiring diagram, connector specifications, required cable length, wire gauge, voltage class, environmental conditions, and any special test standards. Our engineering team will design a new energy vehicle power battery wiring harness precisely to your needs.

Q2: Do you perform quality inspection before shipment?

A2: Every harness undergoes 100% electrical testing (continuity, insulation resistance, and withstand voltage). Additional mechanical or environmental tests are performed if required, ensuring the product is fully compliant before delivery.

https://www.cable-sf.com/New-Energy-Car-Wiring-Harness.html

Dongguan Shuofeng Electronics Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.